Why Powder Coating Beats Everything Else

In the world of countertops and surfaces, durability, aesthetics, maintenance, and environmental impact all matter. Powder coating delivers on all these fronts...and often outperforms traditional finishes and materials. Below, we’ll dive into why powder coating is a top choice and when it makes sense over alternatives like liquid paints, granite, quartz, and raw metals.

What Is Powder Coating?

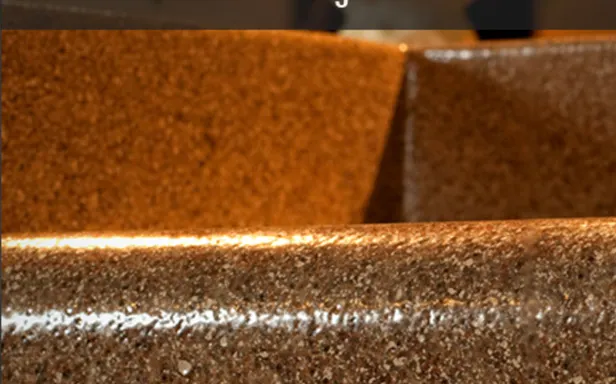

Powder coating is a finishing process in which a dry powder (often a mix of resin and pigment) is electrostatically applied to a surface, then cured under heat to form a hard, continuous coat. It’s especially common for metals, though newer technologies can expand compatible substrates. Wikipedia+1

Key Advantages of Powder Coating

Here are the main benefits—why powder coating tends to beat out the competition:

1. Durability & Longevity

Powder-coated surfaces resist chipping, scratching, fading, and general wear and tear far better than liquid paints. The curing process bonds the powder tightly to the substrate, which helps the finish last for many years—often 15-20+ (depending on exposure, usage).

2. Resistance to Corrosion, Chemicals, and Environmental Damage

Powder coating provides excellent protection against rust and corrosion. For surfaces exposed to moisture or harsh environments, this is a strong plus.

UV resistance: Some powder coatings resist fading from sun exposure much better than many painted finishes.

3. Wide Range of Finishes & Colors; Design Flexibility

Many textures and finishes are possible—matte, glossy, textured, metallic, etc.

Good color stability over time; vibrant hues that last.

4. Lower Maintenance & Better Lifecycle Cost

Because the finish resists damage and degradation, less frequent refurbishing or repainting is needed. That means less cost and less hassle over time. Cleaning tends to be easier; often just mild soap and water, with less risk of damage from cleaning chemicals.

5. Environmental & Safety Benefits

Powder coating typically involves little to no volatile organic compounds (VOCs). Wet paints often use solvents that emit VOCs, which are harmful to health and air quality. Overspray (powder that doesn’t initially adhere to the piece) can often be collected and reused, which reduces waste.

How It Compares to Other Materials / Finishes:

Powder Coating vs. Liquid Paint

Why It Wins:

Powder coating forms a thicker, tougher layer that resists scratches, chips, and fading much better than wet paint. It also has no drips, runs, or uneven spots.

What To Note:

Touch-ups can be trickier, and it requires curing in an oven during the application process.

Powder Coating vs. Clear Sealants (like polyurethane or epoxy)

Why It Wins:

Unlike sealants that can yellow, peel, or require frequent reapplication, powder coating cures into a permanent protective layer.

What To Note:

Sealants can be easier to refresh on wood or stone surfaces, while powder coating is typically for metal.

Powder Coating vs. Bare Metal (stainless, carbon steel, aluminum)

Why It Wins:

Bare metal scratches, rusts, or corrodes over time. Powder coating adds a barrier that makes it heat-resistant, and much easier to clean.

What To Note:

Some people like the raw industrial look of metal; powder coating changes that aesthetic.

Ideal Use Cases

Powder coating is especially good when you need:

° Surfaces used outdoors or with exposure to weather, moisture, or UV (e.g. outdoor kitchen counters, metal railings, sinks)

° High-traffic surfaces that get frequent use (commercial kitchens, bars, etc.)

° Custom colors / textures that need to maintain integrity over time

° Low-maintenance living (grandma friendly 😊)

Things to Watch Out For

To be fair and keep credibility, here are some of the limitations or considerations when using powder coating:

The substrate must usually be metal or conductive, or special methods are needed.

Curing requires heat (an oven or thermal process), which adds complexity and energy cost.

Repairing deep damage (big chips, gouges) can be harder; matching color/finish precisely can be more difficult than with standard paint touch-ups.

Conclusion

If you're looking for a finish that holds up well over time, resists damage, needs less upkeep, and can be beautiful and customizable, powder coating is a strong contender—often beating traditional paints, some stone choices, and other standard finishes. It’s not perfect in every scenario, but for many people (especially those who want beauty plus durability with less fuss), it hits the sweet spot.

ABOUT

Impervicote is a premium provider of powder-coated metal countertops.

Built in partnership with S.A.E.F., our craftsmanship blends industrial strength with sleek design.

Based in the heartland, we’re redefining what a countertop can be.

Impervicote: A better solid surface.